Artificial Intelligence

Wind Turbine Inspection: A Guide

Performing routine inspections on wind turbines is essential for maintaining their efficiency and extending their lifespan. Wind turbines are subjected to harsh environmental conditions, and their intricate designs make inspections both labor-intensive and hazardous. These inspections play a crucial role in detecting major issues like delamination, internal damage, and other factors that could lead to decreased energy production.

Wind turbine inspections involve examining the primary components that enable these structures to generate electricity. Regular inspections help in tracking wear and tear and ensuring that the turbines continue to operate optimally. As the global push for renewable energy intensifies, the demand for skilled wind turbine technicians is projected to rise by 60% over the next decade. However, despite their environmental benefits, wind turbines face challenges, particularly concerning their blades. Made primarily of fiberglass and non-recyclable resins, turbine blades have an average lifespan of about 25 years. While this might seem like a long time, the growing number of wind farms is leading to an accumulation of waste, creating a pressing need to extend blade lifespans through consistent inspections and maintenance.

### Types of Wind Turbine Inspections

Wind turbine inspections span various stages of the turbine lifecycle, including:

- During and post-manufacturing

- Transporting components to the work site

- Building turbines in the field

- Warranty claim assessments

- Monitoring construction progress of wind farms

- Evaluating operational performance

- Preventive maintenance and damage assessment

Regular inspections ensure that all parties involved in the project are kept informed about the quality and performance of the turbines. Since wind farms are costly to establish and maintain, efficiency is paramount. Reducing the levelized cost of energy (LCOE) remains a significant objective for the industry.

### Key Components of a Wind Turbine

The critical parts of a wind turbine include:

- Turbine blades

- Main bearings

- Generators

- Gearboxes

- Nacelle (housing for critical components)

### Blade Inspections

The blades of a wind turbine are responsible for converting kinetic energy into mechanical energy, driving the generation of electricity. Continuous exposure to the elements and operational wear can lead to blade damage. To meet rising energy demands, existing turbine technologies are being enhanced for better performance. For instance, modern turbine blades can reach lengths of over 260 feet—longer than the wingspan of a Boeing 747. With such expansive surfaces, all components of the turbine experience increased stress. As wind farms expand, blade inspections are becoming increasingly important to prevent failures and ensure optimal energy production.

### Methods of Wind Turbine Inspections

A wind turbine blade consists of fiberglass and composite materials that are prone to issues under certain conditions. Even minor surface defects can reduce aerodynamic efficiency and energy output.

#### Surface Inspection

Surface inspections rely on visual techniques like cameras, drones, or the human eye to spot problems such as:

- Surface cracks

- Leading-edge erosion

- Lightning strikes

- Bird strikes

- Delamination

- Leading or trailing edge splits

Regular surface inspections allow for timely corrective maintenance, preventing further damage and extending the lifespan of the turbine without sacrificing energy output.

#### Sub-Surface Inspection

Internal structures of turbine blades can suffer from failures during manufacturing or in the field. Sub-surface inspections employ methods like thermal imaging, shearography, ultrasound, electromagnetic, radiography, and visual inspections within the structure. These non-destructive techniques use contactless technologies to detect flaws beneath the surface, such as damaged shear webs, cracks, manufacturing defects, and bonding erosion.

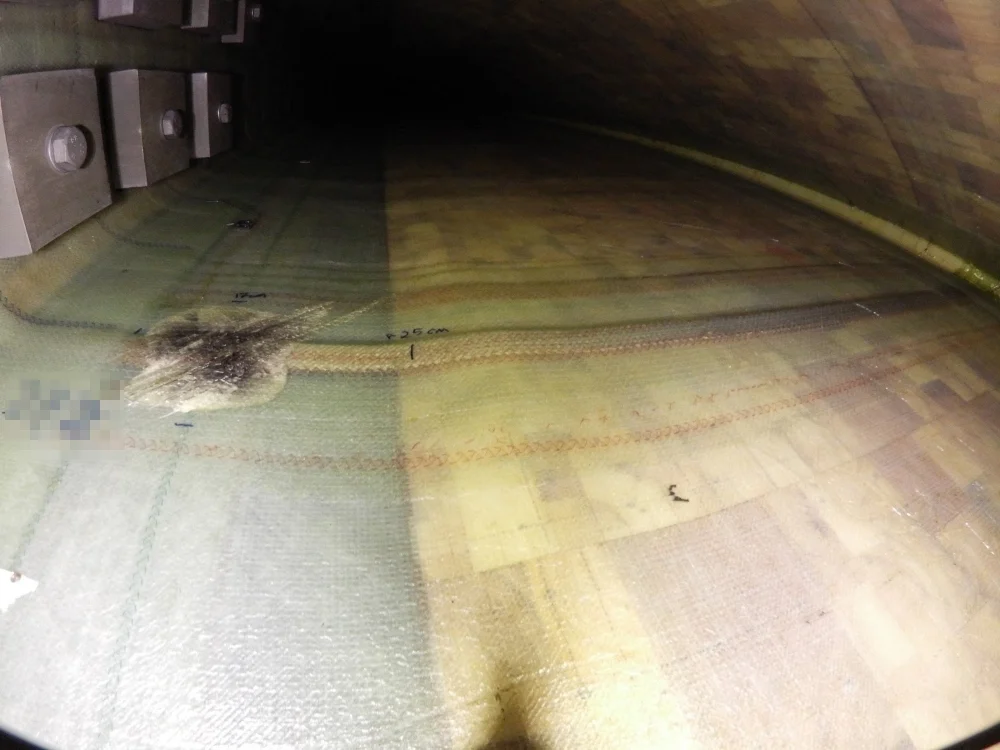

#### Internal Inspection

Internal inspections involve technicians climbing into the turbine blades to examine their interiors. However, legal restrictions limit access to only 91 feet (28 meters) inside the blade, leaving much of the structure unexamined. This method is also risky, expensive, and inefficient. Each blade is divided into two sections, requiring thorough visual checks for cracks, damaged hardware, and other potential failures. Corrosion from salty air is another concern in offshore wind farms.

With hundreds of turbines needing annual inspections, manually accessing each blade compartment is unsustainable. Fortunately, drone technology is revolutionizing the industry, making inspections safer, faster, and more cost-effective.

### Traditional vs. Modern Wind Turbine Inspections

Traditionally, rope access technicians conduct wind turbine inspections. These professionals use ropes and tethering systems to climb turbines for visual checks, maintenance, and repairs. Turbines must be shut down for manual inspections, which leads to lost energy and revenue. Other drawbacks include the dangers of working at heights, the inefficiency of "knocking" on blades to assess their integrity, and the challenges posed by wind noise and adverse weather conditions.

The renewable energy sector is transitioning toward drone technology to enhance safety, efficiency, and profitability. Drones enable inspectors to remain safely on the ground while gathering comprehensive data in real-time. Artificial intelligence and advanced sensors provide actionable insights, and drones can inspect turbines without shutting them down, thus avoiding revenue losses.

#### Benefits of Drone Inspections

- Interchangeable sensors for diverse inspections

- Higher efficiency with faster data collection

- High-resolution images revealing defects invisible to the naked eye

- Applicable to both onshore and offshore wind farms

- Lower operational costs compared to traditional methods

- Eliminates worker risk at great heights and in tight spaces

- Real-time data available on ground control stations

- Capable of inspecting the interior of blades

As the world shifts toward cleaner energy sources, the demand for wind turbine drone inspections will skyrocket. More turbines mean more inspections, necessitating smarter and more efficient solutions.

### How Often Are Wind Turbines Inspected?

Inspection schedules vary but generally occur two to three times a year. With drones, the frequency could increase due to their efficiency and cost-effectiveness.

### Cost of Wind Turbine Drone Inspections

Drone service costs depend on equipment, location, and expertise. Using UAVs typically costs between $300-$500 per turbine, which is roughly 20-25% of traditional inspection expenses.

### Best Drones for Wind Turbine Inspections

Drones reduce inspection time and costs while enhancing safety. Here are some top options:

#### Internal Drones

The Flyability Elios 3 stands out as an indoor solution, designed for confined spaces. Its spherical casing and FlyAware software enable autonomous inspections. Dual thermal/4K cameras and dust-proof lighting systems help identify issues like cracking and corrosion. The Elios 3 also features modular payload bays for LiDAR mapping and auxiliary payloads.

#### External Drones

For external inspections, the DJI Matrice 300 RTK and DJI Mavic 2 Enterprise Advanced are popular choices. The Matrice 300 RTK offers extended battery life and advanced safety features, while the Mavic 2 Enterprise Advanced provides dual thermal sensors for pinpointing small defects. Skydio X2 excels with its 360 Superzoom and 100x optical zoom, ideal for detailed surface inspections.

As the renewable energy sector grows, drone inspections will become indispensable tools for maintaining efficient and reliable wind turbines.

---

*Note: This article explores the evolving landscape of wind turbine inspections, highlighting the transition from traditional rope-based methods to advanced drone technology.*

Our PDC Drill Bits (Polycrystalline Diamond Compact) are engineered to tackle the toughest drilling challenges with unmatched efficiency and durability. Designed for professionals who demand peak performance, these bits deliver faster penetration, longer lifespan, and reduced operational costs.

Why Choose PDC Drill Bits?

Cutting-Edge Material: Features ultra-hard polycrystalline diamond cutters (PDC) bonded to tungsten carbide, ensuring exceptional wear resistance in abrasive formations.

High-Speed Drilling: Optimized blade design and hydraulic efficiency maximize ROP (Rate of Penetration), saving time and fuel.

Versatile Performance: Ideal for soft to medium-hard formations like shale, sandstone, and limestone.

Key Applications

Oil & Gas Exploration: Drill faster and deeper in directional or horizontal wells.

Geothermal & Mining: Efficiently penetrate hard rock and abrasive layers.

Water Well Drilling: Reliable performance in varied geological conditions.

Custom Solutions for Your Needs

We tailor PDC drill bits to your specific requirements:

Customized Cutter Layouts: Match formation hardness and drilling parameters.

Specialized Hydraulic Designs: Optimize fluid flow for cooling and debris removal.

Adaptable Sizes: From 3.5” to 26” diameters, compatible with all major rig systems.

Service Advantages

Expert Support: Our engineers analyze your drilling data to recommend the best bit design.

Fast Delivery: Global logistics ensure timely replacements to minimize downtime.

Cost Savings: Longer bit life and fewer trips mean lower cost per foot.

Upgrade to PDC Drill Bits – where cutting-edge technology meets relentless durability. Contact us today to optimize your drilling operations!

pdc drill bit cost, pdc drill bit price, pdc drill bit specifications, pdc drill bits for sale, pdc drill bit full form

Zigong Tianyi Industry Co., Ltd , https://www.tyalloypins.com