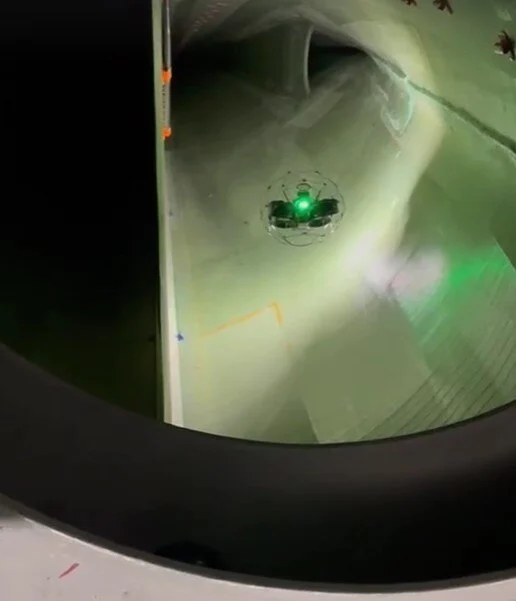

Explore how the Elios 3 drone transformed wind turbine blade inspections, delivering results in just one day instead of five! Safety Inspecting the inside of a wind turbine blade involves working at great heights and in tight, enclosed spaces. The Elios 3 eliminates the need for human entry, significantly reducing risks and improving overall safety. Speed The Elios 3 completed an entire blade inspection in just 27 minutes. Traditional methods, like using a rover or sending a person inside, could take over 2 hours or even 2 days. This makes drone inspections the fastest and most efficient option available. Data Quality Equipped with a 4K camera and LiDAR technology, the Elios 3 captured high-resolution images and detailed 3D point clouds. This allowed inspectors to spot lightning damage, previous repairs, and other critical issues along the full length of the blade. Access With its compact design, the Elios 3 can easily maneuver into each blade from the hub. It doesn’t require repositioning to inspect both sides of the shear webs, making it possible to reach almost the entire length of the blade remotely. According to the Global Wind Energy Council, there are more than 341,000 wind turbines installed worldwide. These massive structures are highly efficient, with the average turbine from 2020 capable of powering a household for a month in just 46 minutes. However, maintaining them is no small task. Wind turbines are located high above ground, often in confined and hard-to-reach areas. Inspecting them requires specialized training, equipment, and time. With the increasing number of turbines, the demand for skilled inspectors is growing, but so are the challenges. In February 2024, Swedish service provider Drone Solution partnered with a wind turbine management company to test if drones could be used for internal blade inspections. While they had already used drones for external inspections, this was the first time they attempted an internal inspection using a drone. Wind turbine inspections focus on detecting manufacturing faults and lightning damage. Lightning strikes may only leave a small mark on the outside, but the internal structure can suffer serious damage that threatens the turbine’s integrity. In some cases, a blade can even explode if the internal components are compromised. Regular inspections are essential to prevent costly failures. A single damaged blade can cost up to $1 million to repair, and wind turbines themselves are expensive to build—often costing around $1 million per megawatt. That’s why effective and efficient inspection methods are crucial. Drone Solution uses the Elios 3 for various challenging inspections, including confined space work. They wanted to show how drones could streamline the process, making it faster, safer, and more cost-effective. Each wind turbine has three blades, and each must be inspected individually. Traditionally, this requires workers to enter the blade, which is a narrow, confined space. The blade tapers as it goes inward, making navigation difficult. Shear webs run along the length of the blade, requiring multiple passes to ensure full coverage. This process is slow, labor-intensive, and dangerous. It typically takes 5–9 days to inspect an entire turbine, depending on blade size. Drone Solution aimed to prove that the Elios 3 could cut that time dramatically. The demonstration involved a turbine with 67-meter-long blades. After completing their training, the team took a 20-minute elevator ride to the hub. There, they positioned two blades at angles (like 10 and 2 o’clock) to allow safe drone operation. The Elios 3 outside of an access hatch on a turbine The Elios 3 was flown into each blade, navigating along both sides of the shear webs. The pilot used the 4K camera to capture visual data and identify potential issues, while the LiDAR scan helped navigate the narrowing space. Each blade was fully inspected in under 30 minutes, with only 3 flights required per blade. After inspecting the interior, the team used another drone to check the exterior of the turbine, ensuring a complete assessment. Snapshot: the Elios 3 flying inside a turbine blade with the shear web on the left Both Drone Solution and their client were amazed by the results. The Elios 3 captured internal damage that was not visible from the outside, proving the value of drone-based inspections. It also eliminated the need for multiple trained personnel and reduced inspection time drastically. Traditionally, this type of inspection would require two people with advanced training. With the Elios 3, only one person needed to be in the hub, significantly improving safety and efficiency. Each blade was inspected in 30 minutes, compared to over a day with traditional methods. Thanks to the success of this trial, Drone Solution hopes to expand the use of drones for wind turbine inspections across more sites. This could revolutionize the industry, making maintenance faster, safer, and more cost-effective for turbine owners and operators alike. 20 Vertical Grain Traction Conveyor 20 Vertical Grain Traction Conveyor,Incline Grain Conveyors,Grain Bin Conveyor,Grain Transfer Conveyor Gongzhuling Huaxi Agricultural Machinery Manufacturing Co.LTD , https://www.hxzbjx.comWind Turbine Blade Inspections with the Elios 3

Key Benefits at a Glance

Why Use Drones for Wind Turbine Inspections?

The sheer size of wind turbines makes them difficult to inspect

The sheer size of wind turbines makes them difficult to inspectPlanning a Wind Turbine Blade Inspection with the Elios 3

The Inspection Process with the Elios 3

Results of the Drone Wind Turbine Blade Inspection