Discover how the Elios 3 proved its worth in wind turbine blade inspections, delivering results in just one day instead of five! Safety Inspecting a wind turbine blade involves working at height and in tight, confined spaces. The Elios 3 reduces risk by eliminating the need for human entry into the blade, making it a safer option. Speed The Elios 3 completed a full blade inspection in just 27 minutes, while traditional methods took over 2 hours with a rover or up to 2 days with manual entry. This makes drone-based inspection the fastest choice. Data Quality Equipped with a 4K camera, the Elios 3 captured high-resolution images of lightning strike damage and previous maintenance work along the blade. Its LiDAR point cloud also helped navigate the complex internal structure with ease. Access Once inside the hub, the Elios 3 could fly directly into each blade without needing repositioning. Its compact size allowed it to reach almost the entire length of the blade, collecting critical data remotely. According to the Global Wind Energy Council, there are more than 341,000 wind turbines installed worldwide. These massive structures are highly efficient, with an average turbine from 2020 capable of powering a household for a month in just 46 minutes. However, maintaining these turbines is no small task. Wind turbines are located high above ground, often in confined and hard-to-reach areas. Inspecting them requires specialized training, such as that offered by the Global Wind Organization, which teaches safe movement, rappelling, and emergency procedures. Finding qualified personnel can be difficult, especially when working at height and in tight spaces. In February 2024, Swedish service provider Drone Solution partnered with a wind turbine management company to test if drones could inspect the inside of wind turbine blades. While they already used drones for external inspections, this was the first time they attempted internal blade inspections with a drone. Drone Solution is among the few operators globally with the expertise to do so. Blade inspections typically focus on detecting manufacturing faults or lightning damage. A lightning strike may only leave a small mark on the outside, but internal damage can be severe and dangerous. In some cases, a blade could even explode if the lightning protection system is faulty or damaged. Regular inspections are essential to prevent costly repairs—sometimes exceeding $1 million per blade. Drone Solution uses the Elios 3 for challenging inspections, including those in confined spaces. Their goal was to demonstrate how drones could efficiently inspect both the inside and outside of wind turbines, offering a faster and safer alternative to traditional methods. Each wind turbine has three blades, each requiring individual inspection. Traditional methods involve trained personnel entering the blade, which is narrow and divided by shear webs—making the process slow and complex. Inspectors must rotate the blade to check both sides of the shear webs, which can take hours per blade. This lengthy and risky process can take between 5 to 9 days for a full turbine inspection. Drone Solution wanted to see if the Elios 3 could significantly speed things up. The turbine used in the demonstration had 67-meter-long blades. Drone Solution’s team had already completed their turbine training before arriving on-site. They took a 20-minute elevator ride to the hub, where access hatches were located for each blade. The turbine was pitched so that two blades were angled upwards, mimicking positions at 10 and 2 o’clock. This ensured that if the drone encountered any issues, it would safely roll back down rather than get stuck. The Elios 3 outside of an access hatch on a turbine The Elios 3 was flown into each blade and along both sides of the shear webs, covering 30 meters of space. The pilot used the 4K camera to capture visual data and identify potential issues, including lightning damage. When the drone went beyond line of sight, the FlyAware LiDAR scan provided real-time navigation assistance. With the help of the LiDAR point cloud, the pilot accurately tracked the drone's position and covered the entire inspection area in just 27 minutes across three flights. The same process was repeated for all three blades. After inspecting the internal structure, the team used another drone to survey the exterior of the turbine. Snapshot: the Elios 3 flying inside a turbine blade with the shear web on the left Both Drone Solution and their client were impressed by the results. The Elios 3 revealed internal damage that wasn’t visible from the outside and was difficult to access using traditional methods. This clearly demonstrated the value of using drones for such inspections. Traditionally, this type of inspection required two trained personnel in the hub. With the Elios 3, only one person needed to be present, reducing risk and effort. Each blade could be inspected in under 30 minutes, compared to over a day with manual methods or 4 hours with rovers. Thanks to the Elios 3, Drone Solution showed that drone-based inspections are not only faster but also safer and more cost-effective. Following this success, they hope to expand the use of drones for regular blade inspections across more wind farms, creating a new and valuable service for their clients. Equipment For Plant Protection Equipment For Plant Protection,Equipment For Plant Protection,Plant Protection Machinery,Plant Protection Equipment In Farm Machinery Gongzhuling Huaxi Agricultural Machinery Manufacturing Co.LTD , https://www.hxzbjx.comWind Turbine Blade Inspections with the Elios 3

Key Benefits at a Glance

Why Use Drones for Wind Turbine Inspections?

The sheer size of wind turbines makes them difficult to inspect

The sheer size of wind turbines makes them difficult to inspectPlanning a Wind Turbine Blade Inspection with the Elios 3

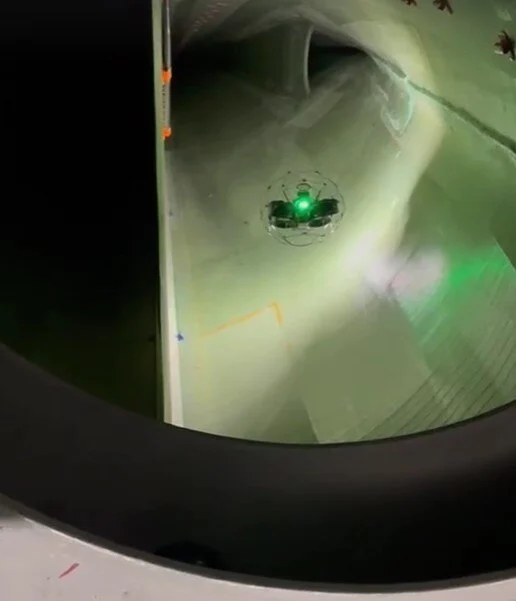

The Process: Drone-Based Blade Inspection

Results of the Drone Blade Inspection