Artificial Intelligence

Wind Turbine Inspection: A Guide

Carrying out a wind turbine inspection is crucial for maintaining the overall efficiency and longevity of wind-powered energy systems. Ensuring that these turbines function optimally is essential, especially as reliance on renewable energy continues to grow. However, inspecting wind turbines is a challenging task due to their immense height and intricate design.

These inspections are vital for spotting core defects, delamination, internal damages, and other issues that can lead to a decrease in energy output. As the global push toward sustainability accelerates, wind turbine technicians are in high demand, with projections showing a 60% increase in jobs within the next decade.

Despite their role in combating climate change, wind turbine blades present environmental challenges. Made from non-recyclable materials like fiberglass and resins, the average lifespan of a blade is around 25 years. While this seems long, the rapid expansion of wind farms means that managing waste from decommissioned blades is becoming a pressing issue. Regular inspections and preventive maintenance are key to extending the life of these blades.

When we talk about wind turbine inspections, it's not just about checking the operational status of the turbine. Monitoring plays a critical role across various stages of the turbine's lifecycle, including manufacturing, transportation, assembly, warranty claims, construction progress, and operational performance. This continuous monitoring ensures that all stakeholders remain confident in the quality and reliability of the turbines.

Critical components of a wind turbine include the blades, main bearings, generators, gearboxes, and the nacelle, which houses and protects these components. Among these, the blades are particularly important since they directly affect energy generation. Over time, the blades endure wear and tear from both operational use and exposure to environmental factors. To meet increasing energy demands, existing technologies are being enhanced, leading to larger blades that span over 260 feet, comparable to the wingspan of a Boeing 747. This increased size adds more stress to the entire turbine system.

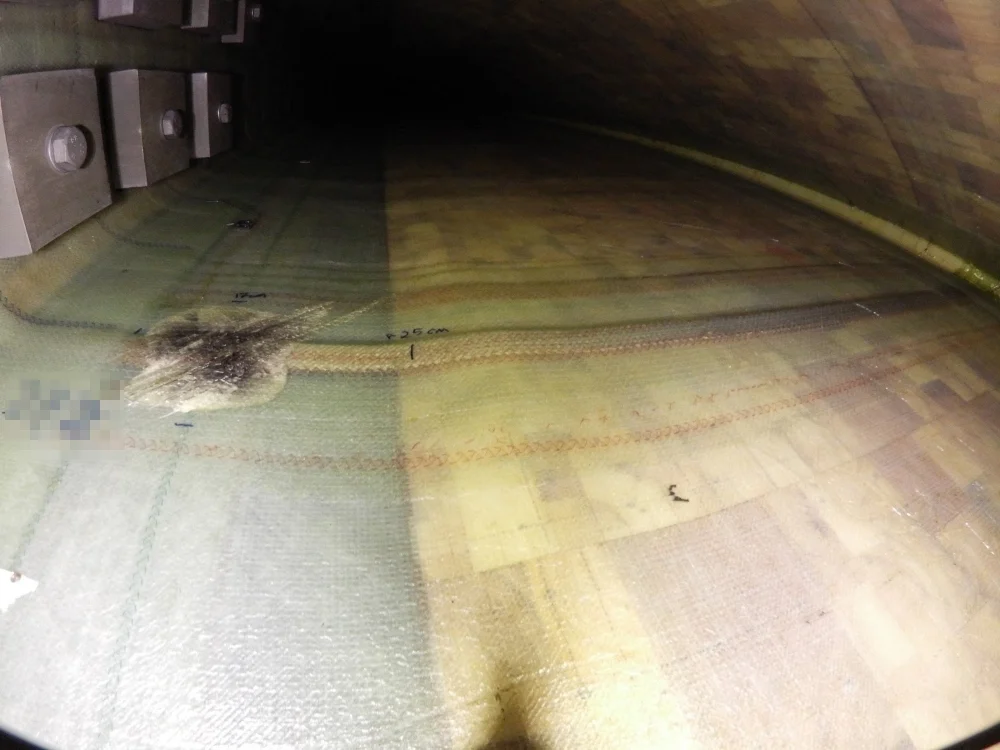

Blade inspections are now a crucial part of preventive maintenance, especially as wind farms expand. Without functional blades, there would be no energy produced. Traditional methods of inspection often involve sending technicians up the turbine, which is risky and time-consuming. The technician is only allowed to go up to 91 feet (28 meters) inside the blade, leaving much of the internal structure unexamined. Furthermore, navigating the confined spaces inside the blades is dangerous, expensive, and inefficient.

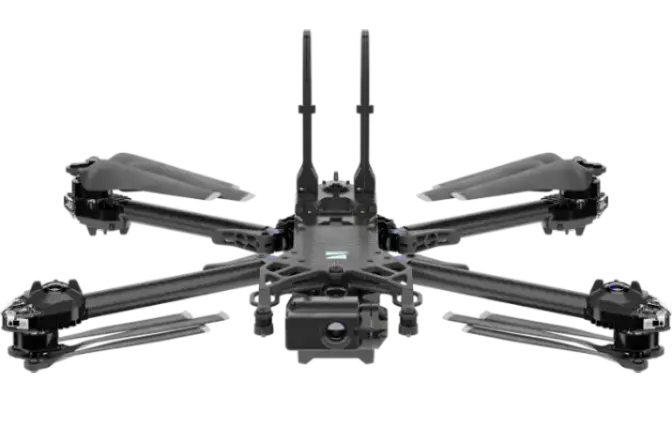

Modern advancements in drone technology are transforming wind turbine inspections. Unlike traditional rope-based methods, drones provide a safer, faster, and more cost-effective way to conduct inspections. Equipped with artificial intelligence and advanced sensors, drones can collect high-resolution data and provide real-time insights. This eliminates the need to shut down turbines during inspections, ensuring uninterrupted energy production.

Drone inspections offer several advantages over traditional methods. They reduce operational costs, minimize risks for personnel, and allow for more frequent inspections. Some drones can even access the internal sections of the blades, providing comprehensive data that was previously unattainable. This shift towards drone technology is not just about safety and efficiency; it’s also about maximizing the lifespan of wind turbines and ensuring they continue to contribute to our renewable energy goals.

As the renewable energy sector grows, so does the demand for drones that can handle complex inspections. Companies like Flyability have introduced drones specifically designed for confined spaces, such as the Elios 3. This drone features a spherical design that allows it to navigate tight spaces and gather detailed thermal imagery and lighting data. Its modular payload system makes it adaptable for various inspection needs, and its real-time mapping capabilities help technicians understand the structural integrity of the blades.

Another popular choice among professionals is the DJI Matrice 300 RTK, which is well-suited for external inspections. With its long flight time, multiple payload options, and robust safety features, it’s a versatile tool for wind turbine maintenance. For smaller-scale operations, the DJI Mavic 2 Enterprise Advanced offers compact yet powerful capabilities, ideal for identifying minor defects on the surface of the blades.

In conclusion, wind turbine inspections are a cornerstone of renewable energy sustainability. By leveraging modern drone technology, the industry can enhance safety, reduce costs, and improve the efficiency of inspections. As we move forward, drones will undoubtedly play an increasingly significant role in ensuring that wind turbines continue to deliver clean, reliable energy for generations to come.

With the rapid growth of the renewable energy sector, it's clear that drones are here to stay. Their ability to provide detailed, actionable data makes them indispensable for the future of wind turbine maintenance. Whether it’s the Flyability Elios 3, DJI Matrice 300 RTK, or Skydio X2, these drones are reshaping how we approach wind turbine inspections.

Designed to withstand the toughest conditions, our VSI crusher parts provide the best durability and efficiency in vertical shaft impact (VSI) crushers, making them ideal for the sand, mining and recycling industries, ensuring optimal performance, reduced downtime and cost-effective operations.

Key Product Features

Exceptional Durability: Made from premium materials like high-grade alloys and tungsten carbide, our VSI crusher parts resist wear and extend equipment lifespan.

Precision Engineering: Designed for optimal particle shape and size, enhancing the quality of crushed materials.

Reduced Downtime: High-performance components minimize maintenance needs, keeping your operations running smoothly.

Application Scenarios

Our VSI crusher parts are widely used in:

Sand Production: Ideal for producing high-quality manufactured sand for construction and industrial use.

Mining Operations: Perfect for crushing hard and abrasive ores, ensuring consistent performance in mineral processing.

Recycling: Efficiently process recycled materials like concrete and asphalt for sustainable construction solutions.

Customized Solutions

We understand that every crushing operation is unique. That’s why we offer:

Tailored Designs: Custom VSI crusher parts to match specific equipment models and operational requirements.

Expert Support: From material selection to installation guidance, our team ensures seamless integration.

Fast Turnaround: Quick delivery of OEM-quality replacements to minimize downtime.

Material Advantages

High-Grade Alloys: Superior strength and wear resistance for extended service life.

Tungsten Carbide: Exceptional hardness and abrasion resistance, ideal for high-impact applications.

Cost-Effective: Durable materials reduce replacement frequency, lowering operational costs.

Choose our VSI Crusher Parts for reliable, high-performance solutions that maximize productivity and minimize downtime. Partner with us to optimize your crushing operations today!

vsi crusher parts, crusher spare parts, impact crusher parts, spare parts for crushers, vsi crusher spare parts name

Zigong Tianyi Industry Co., Ltd , https://www.tyalloypins.com