Copper Fittings, Welded type, Tin rings, Solder Joint Copper Fittings SUZHOU YOUDE ELECTRIC CO., LTD. , https://www.unitekool.com

Torque is a frequently mentioned term in solar photovoltaic (PV) system inspections, referring to the process of tightening a mechanical fastener. These fasteners can vary greatly in purpose, including securing structural components, making electrical connections, and ensuring weatherproof seals on conduits and enclosures.

This concept holds significant importance for both owners and financiers. Faulty torquing is often at the heart of severe electrical and mechanical failures, yet it’s one of the simplest problems to prevent. Maintaining diligence throughout construction and operations & maintenance activities can completely eliminate this issue.

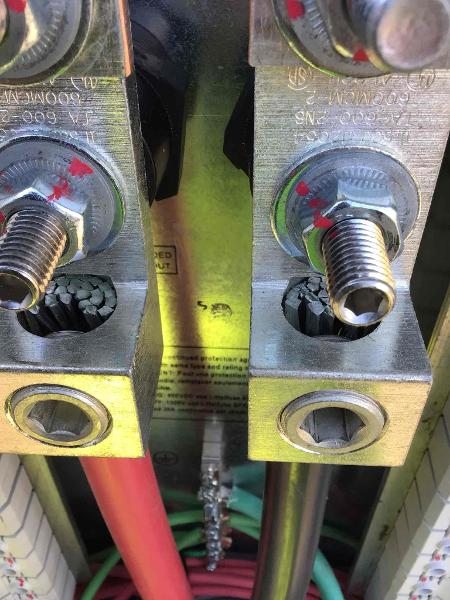

*Image 1: Mechanical Lug*

*Image 2: Compression Lug*

*Image 3: Structural Bolt*

*Image 4: Failed Torque Demonstration (hot spot due to poor torque)*

There are two primary ways hardware can fail due to improper torquing:

**Over Torque**: When the applied force exceeds the specified limit, it may result in:

- Galling of hardware, where the bolt and nut weld together, requiring the bolt to be cut off.

- Stressing the hardware beyond its limits, leading to premature failure.

- Deformation, causing damage to the bolted connection.

**Under Torque**: When the applied force falls short of the required specifications, it could lead to:

- Components coming loose under environmental stressors like wind or snow.

- Electrical connections heating up, potentially causing arcs or fires.

To ensure success in maintaining proper torque:

**Step 1 - Documentation and Planning for Construction**

Start with comprehensive documentation and tooling during construction. Look for:

- All torque values clearly stated in relevant drawings or manuals for each task and fastener type.

- Tools that match the specific task and are regularly calibrated.

- Avoid battery-powered tools unless they have an under-torque lockout feature to prevent under-torque caused by low battery voltage.

**Step 2 - Diligence During Construction Quality Control Inspections**

Quality control methods are crucial during construction:

- Mark all inspected connections to minimize the gap between inspection and actual work done.

- Use UV-rated paint markers to mark mechanical connections, ensuring visibility for years.

- Apply QC gel to electrical connections to detect any tampering visually.

- Keep detailed test records with clear target limits, pass/fail notes, and photos if failures occur.

**Step 3 - Long-Term Inspections and Maintenance**

The final step involves long-term health checks:

- Conduct infrared (IR) thermal scans to identify potential hotspots over time.

- Perform visual inspections for wear, tear, or corrosion on mechanical fasteners.

One major pitfall to avoid regarding torque is re-torquing electrical connections, which should ideally be a one-time event. Instead, use IR scans to pinpoint under-torqued hardware that might need attention.

Who can guarantee correct torquing practices? Pure Power employs field engineers specializing in quality control inspections, commissioning, and construction oversight. They ensure your installers adhere to proper torquing procedures.

By following these steps and maintaining vigilance, you can significantly reduce the risk of catastrophic failures in solar PV systems, safeguarding investments while ensuring operational efficiency.