Density is a fundamental physical property that describes the mass of a substance per unit volume. In scientific terms, it's calculated as the ratio of mass to volume, represented by the formula p = m/V, where p stands for density, m for mass, and V for volume. Stainless steel 304 density The chemical composition of 304 stainless steel includes several elements, with nickel making up about 8%. This composition gives the material excellent ductility, formability, weldability, and resistance to high temperatures, making it easy to work with in manufacturing processes. Due to its versatility, 304 stainless steel is widely used in various industries, from construction to food processing, where durability and corrosion resistance are essential. AISI 304 chemical composition SS 304 mechanical properties AISI 304 stainless steel is known for its excellent formability, which makes it ideal for bending, machining, and welding. Its flexibility allows for the creation of complex shapes, expanding its use across many industries such as automotive, aerospace, and architecture. This property ensures that manufacturers can produce customized products without limitations, offering great adaptability for diverse applications. SUS304 physical properties Stainless steel 304 equivalent Heat Resistance of SS 304 material AISI 304 Forging and Hot Working AISI 304 stainless steel exhibits good corrosion resistance, making it ideal for environments where rust and oxidation are concerns. It is commonly used in kitchenware, marine equipment, and industrial components due to its ability to withstand harsh conditions over time. Heat treatment methods vary depending on the application and desired properties, including annealing, hardening, and tempering, each affecting the material’s characteristics differently. Heat Treatment of SUS 304 AISI 304 material standard Comparison of density of DIN 1.4301 with other materials How to calculate the density of Alloy 304 grade To determine the density of AISI 304 stainless steel, you need to know the mass and volume of the material. The formula is: Density = Mass / Volume Weight calculation of INOX 304 Tube / Pipe Round shape: W = (OD - T) × T × 0.0031416 × Density Square shape: W = (OD × 4 / 3.14 - T) × T × 0.0031416 × Density Rectangular shape: W = ((OD1 + OD2) × 2 / 3.14 - T) × T × 0.0031416 × Density Plate / Sheet W = T × Width (m) × Density Bar Round Bar: W = 0.0007854 × O.D. (mm)² × Density Flat Bar: W = 0.001 × Width (mm) × T (mm) × Density Hexagon Bar: W = 0.000866 × I.D. (mm)² × Density Square Bar: W = 0.001 × Width (mm)² × Density Relations of Temperature And Pressure with Density The density of AISI 304 stainless steel is affected by temperature and pressure. As temperature increases, density decreases, while an increase in pressure generally leads to an increase in density. Annealing at 1,100–1,150°C improves the mechanical and corrosion resistance properties of 304 stainless steel. This process reduces internal stresses, lowers hardness, and enhances the material’s flexibility, making it easier to work with during manufacturing. Thermal expansion is a key factor in engineering applications. The coefficient of thermal expansion measures how much a material expands when heated, which is crucial for design and performance considerations. Mean Coefficient of Thermal Expansion of UNS S30400 The presence of chromium in 304 stainless steel provides excellent resistance to rust and corrosion. Chromium reacts with oxygen in the air to form a protective layer, preventing oxidation and ensuring long-term durability. Higher chromium content typically results in better corrosion resistance, making 304 stainless steel a preferred choice in applications where appearance and maintenance are important. Thermal Conductivity of 1.4301 stainless steel material Auto Structural Components Injection Mould car structures mold,Auto Structural Components Plastic Mould,car structures injection mold,Automotive Expansion Tank Plastic Mould,car connector injection mould Dongguan Hongke Plastic Precision Mould Co.,Limited , https://www.hongkemold.com

Table of contents

Stainless Steel

Density (lb/in³)

Density (g/cm³)

Density (kg/m³)

Density (kg/dm³)

Density (lb/ft³)

304

0.286

7.93

7,930

7.93

495.05

304 ss grade has a minimum of 8% nickel, Refer INOX 304 chemical composition

Property

Measurement

Tensile strength

505 MPa – 620 MPa

Yield strength

~ 215 MPa

Elongation

50% – 60%

AISI 304 material have very good formability, Check UNS S30400 physical properties

Property

Density, lb/in³

Modulus of Elasticity, psi

Coefficient of Thermal Expansion, 68-212°F, /°F

Thermal Conductivity, Btu/ft hr °F

Specific Heat, Btu/lb °F

Electrical Resistivity, Microohm-in

304

0.285

28 x 10â¶

9.2 x 10â»â¶

9.4

0.12

28.3

Grade

UNS

Japanese JIS

Old British

Euronorm

Swedish SS

BS

En

No

Name

304

S30400

SUS 304

304S31

58E

1.4301

X5CrNi18-10

2332

Intermittent service

up to 870°C

Continuous service

925°C

Forging

925–1260 °C

Hot Working

1149–1260°C

Good corrosion resistance is exhibit by Alloy 304 grade, View Heat Treatment of 1.4301 stainless steel

Heat Treatment

1149 – 1260°C

Product

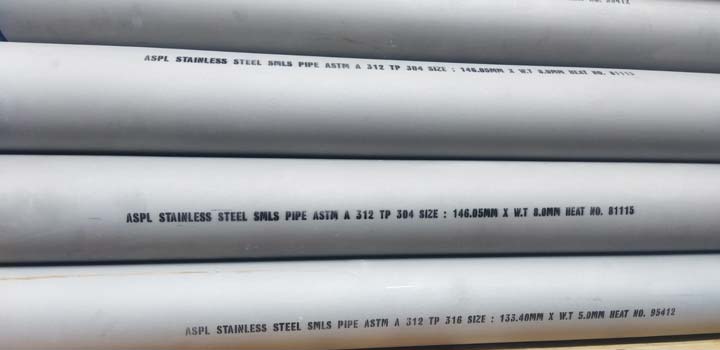

Standard

Plate

ASTM A240 / ASME SA240

Flange / Forged Fittings

ASTM A182 / ASME SA182

Pipe Fittings

ASTM A403 / ASME SA403

Fasteners

ASTM A194 / ASME SA194

Types Of Steel

Density, g/cm³

Density, lb/ft³

Density, kg/m³

Density, lb/in³

Stainless Steel

7.7-8.0

481-499

7,700-8,000

0.278-0.289

Mild Steel

7.85

490

7,850

0.284

Medium Carbon Steel

7.83

489

7,830

0.283

High Carbon Steel

7.81

488

7,810

0.282

Iron

7.87

491

7,870

0.284

Annealing temperature of 304 stainless steel is between 1,100 and 1,150°C, Check Thermal Expansion of SUS 304 material

0-100°C

0-315°C

0-538°C

17.2 μm/m/°C

18.4 μm/m/°C

16.2 μm/m/°C

Chromium prevents rust and corrosion in SS 304 material, View Thermal Conductivity of DIN 1.4301

at 100°C

at 500°C

16.2 W/m·K

21.5 W/m·K

Chromium

20%

Nickel

10.5%

Carbon

0.08%

Manganese

2%

Silicon

1%

Phosphorous

0.045%

Sulphur

0.03%

Nitrogen

0.1%